Direct to Garment

From t-shirts and hoodies to bags and accessories

Start your business today in 3 simple steps:

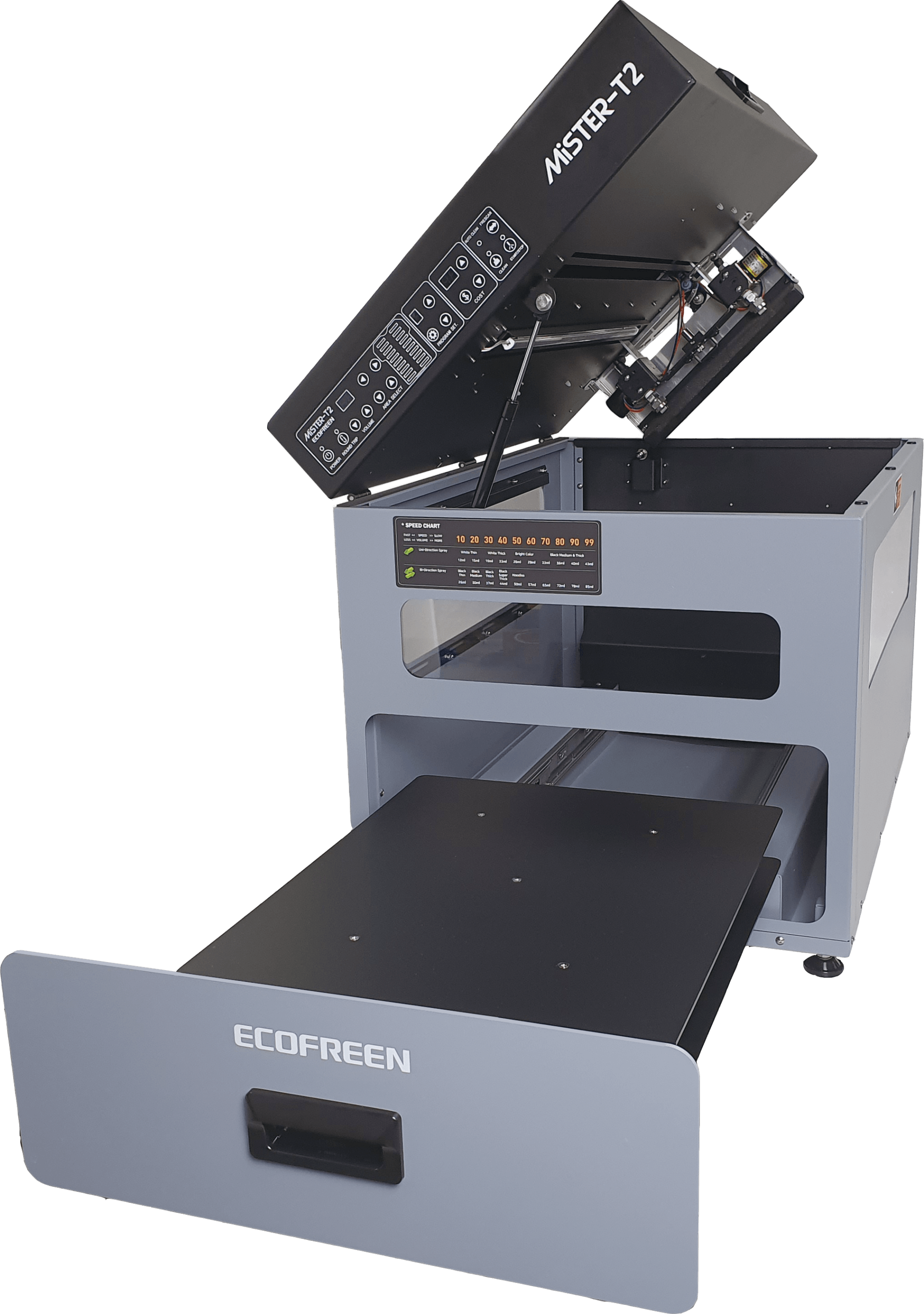

Step 1 - Invest in a Machine

Your choice of printer, RIP software, ink and pretreat are incredibly important to the success of your business. They need to work well together to ensure that you’re getting the best possible image reproduction, whilst also remaining cost effective.

Most manufacturers have their own line of ink and pretreat available.

Step 2 - Invest in a Press

A good quality heat press is essential, as it’s responsible for removing moisture from your garments before printing, as well as for curing ink into the fabric once printing is complete.

If your heat press doesn’t hold its temperature properly, it will affect your finished product.

Step 3 - Choose your Garment

Garment choice is vital for the final product you will ultimately create.

This is why you should choose garments that have been manufactured with garment decorators in mind. AS Colour, Ramo and Baby Blanks are brands that are particularly suited to DTG printing.

"We would like to sincerely thank Gus from Machines Plus for his commitment and dedication to us when we were in the market for a new DTG printer and starting out in a brand new printing business. The level of expertise shown by Gus during our training helped us to develop our experience quite quickly. 4 thumbs up from the Shirts 24/7 team!"

Ryan Cobb - Shirts 24/7

FAQs

Got a question? We're here to help.

-

Why should I choose DTG over other garment decoration methods, like screenprinting?

Direct to garment allows for a much wider range of colours, tones and effects than traditional screenprinting. It also produces a much higher quality output than is possible via transfers. DTG inks are water based, which means that prints are softer to the touch, and it allows you to offer your customers on-demand printing of one-off designs as well as small to medium sized production runs. There aren’t any screen or film setup costs involved, and you will also have complete control over your inventory.

-

What sort of learning curve should I expect?

This will vary based on your experience and the amount of time you actually dedicate to mastering the process. If you have a good background in graphics and textiles, you’ll generally have a shorter learning curve than those who don’t. Although we offer training with each machine sale, it is important to remember it will take some practice to master the skills. Most people are proficient within a few months. As with any type of garment decoration - being acceptable and being skilled are two very different things.

-

How much does it cost to print a t-shirt?

This is a hard question to answer, as it depends on a handful of factors. How much of the garment does the print cover? Is it on a light or a dark tee? How many layers of ink are you laying down? What saturation levels are providing you with the desired results? Typically, it will cost a couple of dollars at most (keeping in mind that darker garments are more expensive to print on than lighter ones). The Epson SC-F2160 actually provides you with a cost estimation if you want peace of mind.

-

Do the garments need any special preparation or after care?

In short, yes. When printing on dark garments, pretreatment is essential. This ensures that the ink bonds to the fibres and that the resulting print will be vibrant. You will then need to press the garment to remove any moisture and ensure a flat printing surface. After printing, you will need to re-press the garment to cure the ink. Whilst it is not essential to pretreat light garments, many people believe that it provides them with sharper prints and more vibrant colours. The aftercare for light garments is the same.

-

Do the prints withstand washing?

Yes, providing that you have properly pretreated and cured the garments after printing, the prints will offer excellent wash fastness. To keep your prints looking as good as new for as long as possible, it’s recommended that you wash garments inside out, in cold water and on a gentle cycle. They should then be air dried or placed into a dryer on a low heat setting (to avoid garment shrinkage). Also keep in mind that better quality garments will be more washfast than lower quality ones.

© 2021 COPYRIGHT MACHINES PLUS | Terms and Conditions | Privacy Policy | Returns Policy | Service Agreement