March 12, 2020

Did you know that TR ink (used by Roland DG’s TrueVIS VG and SG Series) will be discontinued by February 2021 and instead replaced by the new and improved TR2 ink?

If you are a current user of the original VG or SG generation printer/cutters, you’ll need to make sure that you’ve converted your machine by then if you want to ensure that you can continue using it (plus take advantage of a host of new features).

- Print, Finish & Install Graphics on the Same Day

Are customers’ demands for faster turnaround times something that has always gotten you frustrated? With the new TR2 ink, you’ll be able to satisfy their demands without compromising on the quality of the finished product - prints will be ready to laminate and then immediately finish after only 6 hours. - New Certifications from Industry-Leading Media Manufacturers

The VG Series using new TR2 ink is certified for long-lasting results by the 3M™ MCS™ Warranty, whilst both the VG and SG Series using TR2 ink are certified by the Avery Dennison ICS™ Performance Guarantee (which provides protection for up to 4 years outdoor durability and up to 7 years indoor). - Produce Stunning Quality, Colour-Accurate Prints

The new ‘True Rich Color’ preset allows you to take full advantage of both series’ great colour reproduction capability, as well as the TR2 ink’s wide colour gamut. There’s no need to compromise on colour vibrancy or accuracy - deliver vivid output whilst maintaining neutral greys, natural skin tones and smooth gradations. - Significantly Reduce Ink Consumption

Thanks to newly developed ink technology, the use of TR2 ink can actually significantly reduce the amount of ink used when performing printer maintenance. This not only means there’s more ink available for your paid jobs, you will find that you won’t have to replace the cartridges as often. - Produce the Most Demanding Applications

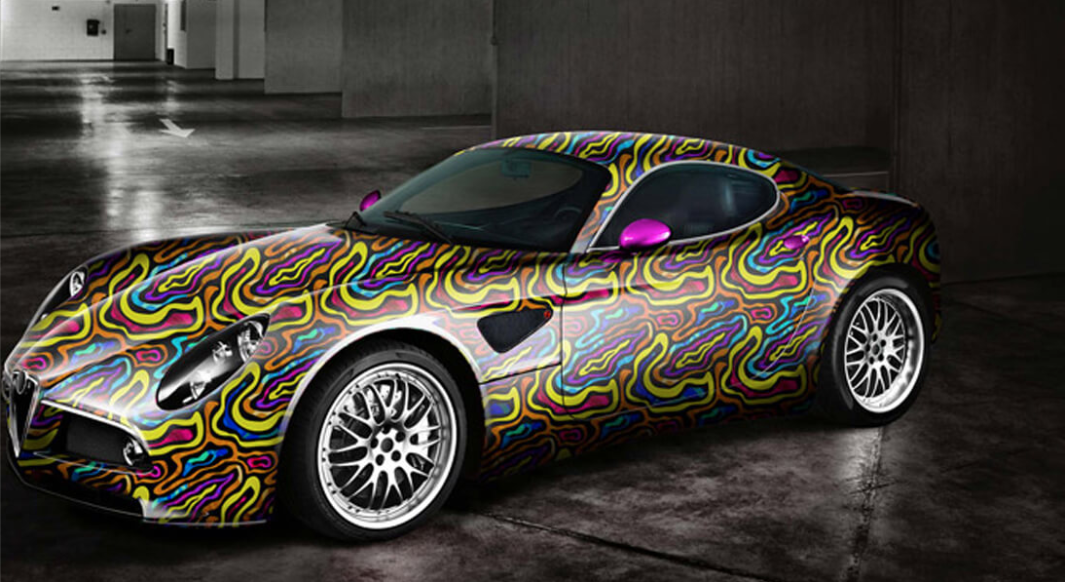

TR2 ink offers outstanding performance for a variety of indoor and outdoor graphics, including some of the most demanding applications where stretch, adhesion and rub resistance are imperative (such as car wraps). It offers up to 200% stretch, as well as delivers unmatched washability.

6. Enhanced Print and Cut Functionality & A Super-Streamlined Workflow

Once the conversion is complete, you’ll benefit from a host of intelligent and intuitive new features on your VG or SG printer/cutter. These features will help to optimise print and cut accuracy, as well as speed up production. They include a new crop mark option, PerfCut Mode, over cut function, and cut and print function.

7. Keep Track of Production Whilst on the Move

Perform even more functions from your smartphone or tablet, from test printing to cleaning. Mobile Panel 2 (available for download in the App Store and Google Play Store) with enhanced Bluetooth connectivity will also send you new push notifications to alert you when a print job or cleaning is completed.

8. Ultimate User-Friendly Operation

Many sequences (such as the workflow of manual cleaning and sheet cut sequence) have been streamlined for efficiency, to reduce user input and to save time. The new Nozzle Mask function will allow you to print using a selectable portion of the printheads, helping to keep your business running in the unlikely event of a printhead issue.

9. Compatible with New (Optional) Media Take-Up System

Once the conversion is complete, your VG or SG printer/cutter will be compatible with a new (optional) media take-up unit - the TU4. It supports 2 modes for improved take-up accuracy for various types of media, as well as a new mode of taking up whilst giving the media some slack.

Although there is still a year remaining before the original TR inks are no longer available, we highly encourage you to think about converting your VG or SG Series printer/cutter sooner rather than later. There is no additional cost for the conversion, you just need to ensure that you have a set of TR2 inks (in the same configuration as your current setup), cleaning liquid pouch and a bottle of cleaning liquid on hand.

Please contact the Machines Plus team for more information or assistance on making the conversion - info@machinesplus.com.au

or 1300 167 587.

Share

Tweet

Share

Mail

By Kristina Wood

•

May 7, 2024

Did you know that out of the 20 Epson SC-F3000 models in Australia, Machines Plus has installed a whopping 9 of them? We're not just about recommending equipment; we're all about providing tailored solutions to meet all your direct-to-garment and printed merchandise needs!

© 2021 COPYRIGHT MACHINES PLUS | Terms and Conditions | Privacy Policy | Returns Policy | Service Agreement