What it looks like and how to get there

When it comes to starting a t shirt printing business, there’s a few things to consider - the technology choices, knowing your numbers and marketing your business. But beyond the decision to step into the world of custom t shirts and apparel:

What do you need to really be successful?

Is this is your first time as a self-employed business? Are you adding merchandise production to your existing business?

Knowing how the successful players do it will give your business a head start, or a power-up.

Here we share 10 insights on what a successful t shirt printing business looks like, using direct to garment printing. And our top tips on how to get there.

1. Understanding what success looks like for you

What’s the reason you’re getting into the t shirt and merchandise game?

We see the most common reasons people get into custom t shirt and apparel printing are:

- Merchandise production is a natural extension to their business

- It’s time to in-source merchandise production and improve margins

- Create a business that works around you and your family

- Create a business you can base from home.

Successful DTG printing businesses understand their main motivation for being in business. And use that to make the best decisions right from the start.

Whatever your reason, direct to garment printing, or DTG as it was previously known, makes custom printing affordable and accessible. It’s many advantages over screen printing has opened up a whole industry for new players over the last 10 or so years. Direct to Garment Printing or DTG printing, is also allowing screen printers to cater for a part of the market they’ve traditionally turned away.

Before direct to garment technology came along, screen printing and embroidery were the main players in town. And that meant customised, short run orders were expensive.

But now with direct to garment, custom orders and shorter productions are possible, thanks to the ability to print a single t shirt, with a rainbow of colours, in less than 1 minute.

2. Qualify your customers

Knowing how to qualify your customers and redirect them to a better solution brings about a win-win for both. When a customer asks you to quote on printing a batch of shirts with a particular colour, fabric or artwork that you know is not going to get the best outcome, then say so. Often times, your clients are looking to you for a better solution.

And sometimes saying no to a job is the best answer.

If you know a quality outcome isn’t going to be achieved, even after talking with your customer, or you’re not going to be able to meet the deadline, then say no. Gus Altmann from Machines Plus says “Most people are happy to pay for quality and they’ll appreciate your honesty if you think what they’re asking is not possible. And they’re the customers you want.”

They’re not the expert. You are.

When it comes to getting the graphics right, Mark Frahm, owner of Mammath T-Shirt Printing

says “Work with the customers to fix the file. Many customers have no idea what is ‘print ready’ artwork. You can educate them by providing the necessary file requirements, but you will always have some artwork to fix. Don’t do that for free. Quote them to prep the file they supplied and they will either pay a little extra to get it right, or go away. Win-win.”

3. The right gear for the job

|

4. Know your numbers

Successful businesses of any kind know their numbers. It’s essential to know:

- Your fixed costs to keep the lights on and the business running;

- Direct costs associated with printing one t shirt or a batch of 50;

- How much margin you’re making on each item you're printing; and

- How you’re tracking against a financial budget that you regularly keep an eye on

How do you know what to charge?

Reaching the profit threshold quickly is critical in any business.

The first place to start is knowing the average cost of printing per item (factoring in your direct costs) and the time to print each shirt. This will vary depending on what printer you’ve got, as production speeds, ink costs and servicing all vary from brand to brand.

The digital decorators who are doing this successfully aim for a profit margin of at least 10-15%. They qualify their customers so they don’t take on jobs that will lose them money or damage their brand.

Generally speaking, you should plan to print at least 30 shirts per week to cover costs and repayments of a printer at $30-$40 per shirt. But this also depends on your cost base and business model.

But determine what’s right for your business.

Know your costs, research the market and set your profit margin.

5. Practice makes perfect

Making mistakes is the best way to really get to know your machine and the tricks of the trade. After setting up their new digital garment printer, new business owners often make the same mistake:

They wait for their first order before they print.

Mark Frahm says “The last thing I want is a dissatisfied customer returning products that have failed. Nothing goes out the door without me knowing that product will be something the customer raves about, not complains about. With such a variety of different compositions and styles of fabric, and artwork, a successful garment printing business should be sampling and wash testing every style and composition of garment they sell, continually, improving and perfecting. The key is to sell a product no-one can complain about.”

So don’t wait for your first order before you put your Direct to Garment Printer through its paces.

6. Know where you’re going

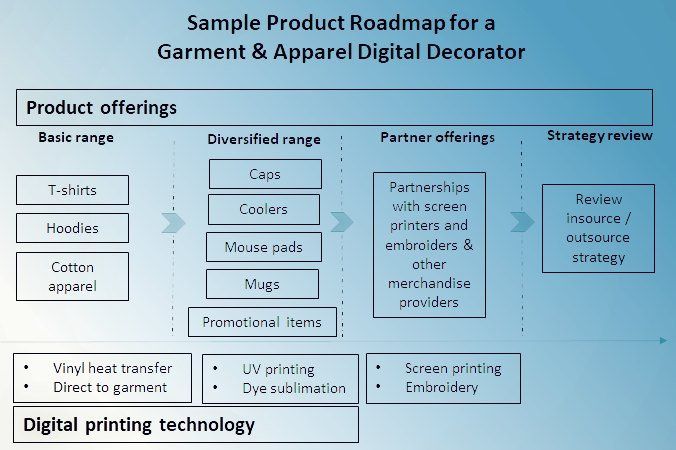

Map out your vision of where your digital decoration business is heading. Is it always t shirts and hoodies? Or do you want to print on caps, mugs and other promotional material to support your customers’ brands?

Most digital decorators know from the get-go that they’d like to get into other promotional items. So talk to your customers now and gauge a level of demand for these items. Establish those relationships early so that it’s you they order from.

Drawing a product roadmap can help you visualise and plan for your business to diversify. It’s likely that your business model will change, as you may need to bring on another staff member and you’ll need to factor into the budget any new technology, such as UV or dye sublimation printer.

Here’s an example of what a product roadmap for a digital decorator might look like:

7. Open up your network

Aside from knowing where you’re going, is knowing what you don’t want to do.

“Knowing your sweet spot is key,” says Gus. “DTG printers are perfect for runs of 1 - 250. Although capable of more, this is where the best market opportunity is for digital decorators using DTG printers.”

Don’t compete with screen printing. Embrace it.

Mark Frahm says “As a successful DTG business, you will receive enquiries to quote on volume orders that are out of the feasible DTG market. Don’t try and run those orders through DTG. Find a trusted screener to hook up with and work together. Find a contract textile screen print company so you can quote, and hopefully outsource larger orders. Screeners will have a bunch of small orders to throw your way in return, so everyone makes money.”

8. Mapping the steps

Successful printers have clear steps of the process, beginning to end. From the initial enquiry, creating a quote, scheduling the order, production, packing, accounting and following up.

Software solutions for accounting and scheduling are also important. So bring these in right from the start, so your business can grow into them.

For DTG production, Mark Frahm says that it’s best to break down pretreat and print as two elements in your process. “You have to visit every print area twice on every garment. I break it down into those two elements and find ways to be faster and more efficient at both.”

9. Have the right attitude

Running any kind of business is tough. Let’s face it. There’s loads of purks running your own home-based business, or being your own boss. But when things get tough, or you’re having ‘one of those days’, it’s up to you to keep yourself going.

The right attitude will help you through the tough times - keeping you in business for the long run.

So what is the right attitude? Gus says “embracing the challenges and using creativity to overcome the obstacles. Digital decoration is an industry for creative thinkers. Choose to look at a tough situation as an opportunity to grow and learn.”

Never Think It’s Easy

Mark Frahm says “No form of textile reproduction is. DTG printing looks easy, often sold as easy, but it’s not. There’s a little more to it than pressing a button. There is a continual learning curve, and there is never a time when you will know it all. The challenges are daily, so you need the right attitude to seize everyday. DTG printing takes commitment, perseverance, and a high level of problem solving skills - all the time.”

Surround yourself with the right support

Your employees, business partners and technology providers should all be there to play a key role in your business. Gus says “having the right support in place is as important as choosing the right technology. Successful players know what they need to do, who they can turn to when they need help with a job that’s not going to plan.”

10. Finding your people

Knowing your target audience, how to reach them and having a product that they want and love, is part of the secret sauce of successful digital decorators. Key ingredients to this secret sauce include:

- Market testing your product

- Creating your community

- Building your brand and message

- Using social media, a website or both

- Helping people find you (Search engine optimisation)

- Amplifying your message and Social proof.

Marketing your DTG printing business is critical. Working ‘on the business’ and just as important as working ‘in the business’.

Make time regularly to improve your marketing.

It might be just you in the business, as opposed to established digital decorators that might have some help with their marketing.

But remember, they were once like you.

Seek out courses, online communities or podcasts (our favourite at the moment is ‘Two Regular Guys’) to improve your marketing skills. The investment will be well worth it in the end.

Over to you

What do you think makes a successful t shirt printing business? Any recommendations to share? Please pop in the comments below:

About Machines Plus

Machines Plus is a digital print supplier for garment and digital decorators, of any business type or size. Gus and the team help digital decorators to get ahead in their business by providing the best brands for DTG garment printing, UV printing, sublimation and heat transfer.

Disclaimer: Any advice, financial or otherwise, in this article is purely the opinion of the author and Machines Plus. Seek professional financial advice before starting any business.

© 2021 COPYRIGHT MACHINES PLUS | Terms and Conditions | Privacy Policy | Returns Policy | Service Agreement